|

China Starwin Science&technology Co.Ltd

|

| Payment Terms: | T/T |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

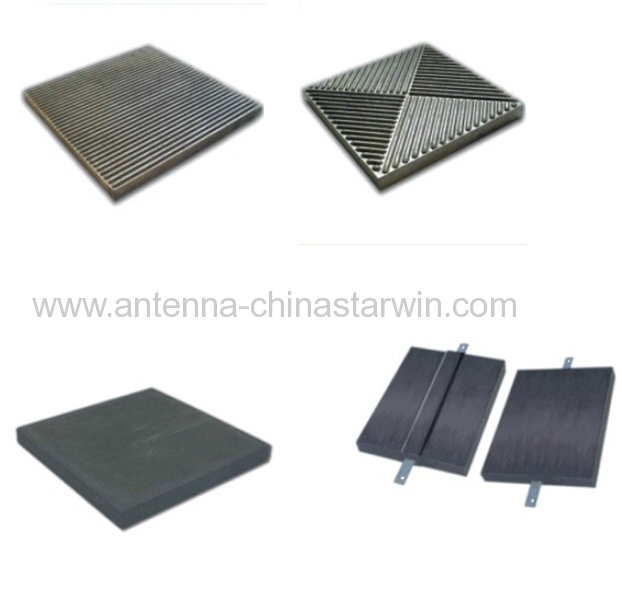

Product Introduction

The grounding body is usually more metal conductor, the most common are angle steel, round steel, steel pipe,

copper rod, copper mesh, its disadvantages are many materials, high cost, life, poor stability, should not be used

in high resistivity soil area. The grounding module is less material, the mouse is small, long service life, good

stability, especially suitable for high soil resistivity area use.

Grounding module using natural nonmetallic inorganic material point compound and into, with good conductive

properties of carbon crystal as conductive materials, as the magnetic absorption material by using high purity

natural iron ore in the iron atom, the carbon crystal and natural iron ore and silicate material size granular as

conductive materials, all materials is a natural inorganic material.Using this material as grounding materials,

various functions of lightning protection, can achieve the safe use of electricity, the prevention and control of

electromagnetic wave. Because of the material with hydration activity, no corrosion(erosion of soil anti acid

and alkali corrosion medium), non-toxic, suitable for any environment. Buried, no pollution to the soil and

underground water source, very environmental protection characteristics. Grounding the service life of the

module has the characteristics of hydration activity can be as long as 100 years.

Working Principle

The grounding module and grounding wire is tightly connected,natural conductive ore and hydrating Portland

good conductivity, excellent soil affinity, water absorption and water retention, reduce soil and grounding

module impedance, so the failure of impulse current rapidly released into the protection function and achieve

the earth.After release of electrolyte buried, make the soil base and contact ionization,increasing the grounding

body itself release current area, reduce the grounding module and the contact resistance between the soil layer,

the characteristics of the cement matrix module itself with water retention and release of extremely strong

electrolyte (these characteristics are metal materials do not), and then play the drag reduction excellent ability of

grounding module. Can be used in the fields of electronics, electric power, transportation, telecommunications,

building,petrochemical and other needed grounding protection of the body.

The Characteristics Of Product Structure

Technical indicators

model | external dimensions(mm) | resistivity | compressible strength | surface area(㎡) | volume(m³) | density(kg/m³) | weight(kg) |

KN-M-300 | 300×300×30 | 0.0098Ω·m | 18Mpa/28d 176kg/c㎡ 2500psi | 0.2388 | 0.002475 | 2383 | 5.9 |

KN-M-450 | 450×450×35 | 0.0098Ω·m | 18Mpa/28d 176kg/c㎡ 2500psi | 0.5242 | 0.006 | 2383 | 14.3 |

The calculation formula of grounding module

According to the soil resistivity grid, use the following formula for calculating grounding module quantity:

After parallel the total grounding resistance:Rnj=Rj/nŋ

Rnj-The total grounding resistance

Rj-Each of the grounding resistance of grounding module(Ω), numerical look-up table (manufacturers)

n-Grounding module number

ŋ-Module adjusting coefficient, normally 0.6-0.9

Product Construction Method

1.The grounding module can be with horizontal and vertical buried depth, it must meet the constant temperature

layer but shall not be less than 0.8m, the deeper the effect to be better.

2.Spacing module and the module suggested by 4m is better, if the environmental conditions do not allow, can

relax or reduced.

3.The bottom line and the grounding module connection by various methods, such as cable crimping terminal

type connection, flat welding connection, if the need to use the fire-clay fusion of connection method.

can purchase the special welding fittings for our company.

4.With the grounding module connected with the dirt, please add water mash-able to benefit its close contacts

with each other to improve the drag reduction effect.

5.Terminal crimping to compaction and tightened the screw, then using 1:2 cement packaging joints, avoid

electrode joint metal parts corrosion, affecting the working life.

6.Please be sure to backfill tamping, so we can get the resistance reduction effect of higher.

Don't add other industry salt and other chlorine salt help resistance reducing material, so as not to damage the grounding module, if you want to get faster resistance reduction effect of higher by fourth more water can be.

Grounding module construction diagram connection:

Applications

1.Power plant, substation, nuclear power plant, hydroelectric power stations, wind power station, switch station,

high voltage transmission lines, electrified railway,telecommunication, mobile communication base station,

microwave relay station,satellite ground receiving station, radar station work base, safety grounding and

lightning protection and grounding.

2.Valuable precision instrument, computer room equipment , program-controlled equipment of Posts and

telecommunications, radio and television equipment,electronic medical equipment working grounding and

grounding protection.

3.Various kinds of high-rise buildings and tall buildings, sites of ancient buildings, tall monument for lightning

protection and grounding.

4.The oil pipeline and oil and gas, inflammable and explosive material warehouse for lightning protection and

grounding.